Customer Support : Cutting FAQ

YAC DAStech is an expert manufacturer of cutting machines and cutting equipment, providing complete service from design to manufacture and sales. Our technicians and personnel explain in simple terms what we can do for you, cutting technologies and support you with answers to your questions and concerns.

Questions

We try to answer any questions about materials (workpieces) that can be cut and processed with examples of specific materials whenever possible.

- QIs circular machining possible?

- QWhat is the appropriate cutting blade for a workpiece (material)?

- QCan metals and resins be cut?

- QCan you cut with a minimum of burrs in aluminum (AL) plates?

- QCan you make a clean cut in stainless steel (SUS) plates?

- QCan you cut copper (Cu) plates?

- QIs it possible to cut (slice) LED heat dissipation aluminum boards without damaging them?

Answers

Is circular machining possible?

- Yes. Core drill machines are used in a highly efficient processing method to cut glass, silicon wafers and crystals into round shapes. Traditionally, workpieces were cut into squares and polished until rounded after adhesive was applied, but there is now a way to cut materials efficiently into round shapes in one step.

Concentric machining and donut (dual blade) processing are also available.

What is the appropriate cutting blade for a workpiece (material)?

- YAC DAStech has diamond blades for cutting a wide range of materials such as glass, ceramic, crystal, sapphire, SUS, nickel, copper, and resin. YAC DAStech Applications Lab and dedicated staff select the optimal blade for each material. Please see also Test Cut under the Customer Support page as well as Blade Sales on this site.

Can metals and resins be cut?

- Nickel, aluminum, copper and stainless steel materials are among the metals that can be precisely cut.

Dry cuts are also available depending on the material.

In addition, cutting can be made on resin and glass epoxy boards. Please consult us.

Can you cut with a minimum of burrs in aluminum (AL) plates?

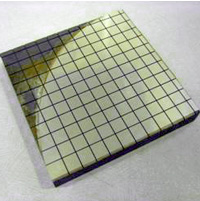

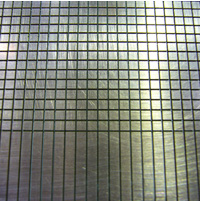

Aluminum (AL) plates (sized 300 x 150 x 1.8 mmt) can be cut to suppress burrs as much as possible deploying a multiblade on a slicer.

*AL plates are an often-used material in LED heat sinks.

Can you make a clean cut in stainless steel (SUS) plates?

SUS plates can be fully and precisely cut minimizing burrs as much as possible on a slicer.

*SUS plates are sometimes used as special heat sinks.

Can you cut copper (Cu) plates?

Copper (Cu) plates can be cut on a slicer under certain cutting conditions to reduce burrs to as few as possible.

*Cu plates are sometimes used as special heat sinks.

Is it possible to cut (slice) LED heat dissipation aluminum boards without damaging them?

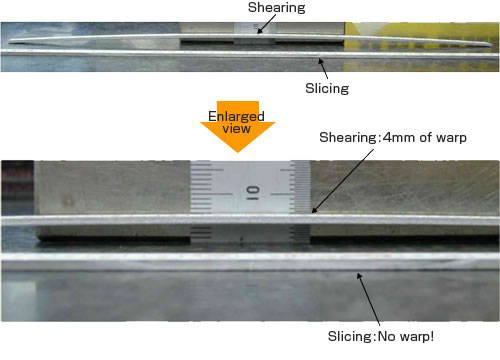

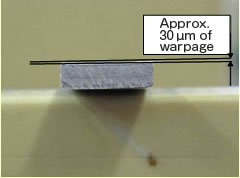

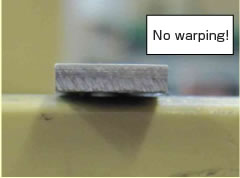

Boards can be cut into clean cross sections without warpage.

Compare conventional shearing and processing on our slicing machine.

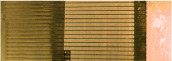

The slice cut retains a clean cross-section from any angle!1. Side : Warpage comparison

2. Cut surface : Comparison

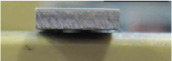

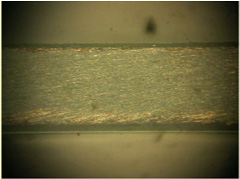

[ Shearing ]

Burrs detected in the cut surface. In addition, the cut surface lacks linear beauty. It is clear that cutting significantly impacts the cut surface.

Burrs detected in the cut surface. In addition, the cut surface lacks linear beauty. It is clear that cutting significantly impacts the cut surface.[ Slicing ]

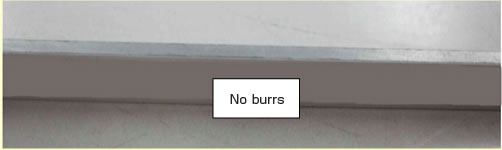

Achieves a clean cross section, unlike shearing. There are no burrs, either.

Achieves a clean cross section, unlike shearing. There are no burrs, either.3. End : Warpage comparison

[ Shearing ] End

[ Slicing ]

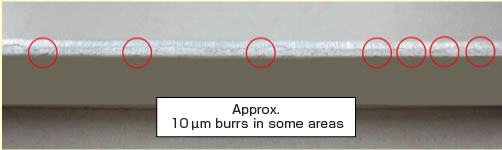

4. Edge view : Burr comparison

[ Shearing ]

[ Slicing ]