Cutting Machine Lineup

Slicing MachinesDAS-65N

- Features/Dimensions

- Suitable Materials

- Structural Advantages

- Standard Specifications

- Download Our Brochure

Improved type of our optimal model for precision machining of hard and brittle materials and metals.

High mechanical rigidity and precision cutting enable high-load cutting and grooving!

Features

- 1. Touch panel for better operability

- 2. Improved indexing with servo motor control

- 3. Improved rigidity of each machine part

Suitable Materials

■ Maximum workpiece size: 450 mm x 150 mm

- Shape

- Type

Structural Advantages

Each axis is controlled by servo motor

Y axis servo motor

Higher indexing accuracy by deploying servo motors to the X, Y and Z axes.

Automatic alignment and operation panel

Right on the spot!

Easy positioning operation

Current position and parameters are on easy-to-read LCD panels.

Simple display for ease of operation.

Standard Specifications

Slicing Machines

DAS-65N

| Chuck table dimension | (mm) | 450×150 | |

|---|---|---|---|

| X axis | Effective stroke Feed speed Fast traverse speed Drive system Drive source |

(mm) (mm/sec) (mm/sec) |

500 0.1~80 80 Ball screw and timing belt AC servo motor |

| Y axis | Effective stroke Index step Fast traverse speed Drive system Drive source |

(mm) (mm) (mm/sec) |

150 0.001 40 Ball screw AC servo motor |

| Z axis | Effective stroke Index step Fast traverse speed Drive system Drive source |

(mm) (mm) (mm/sec) |

100 0.001 20 Ball screw and worm gear (1/20) AC servo motor |

| Spindle | Bearing type Maximum rotation speed Rotation speed control method Motor Blade Safety interlock |

(min-1) |

Belt drive, mechanical bearing 8,000 Continuous variable control (inverter) 3.7KW 2P low vibration motor φ4" - φ6" 1.Spindle stops at the waterproof cover open. 2.Spindle will not rotate with cover unclosed. 3.Splash cover is locked during spindle rotation. (Option) |

| Operation panel | Touch panel | Showing the operation switch, cutting data, parameter setting, error massages, etc. |

|

| Accuracy | Table top accuracy Yawing along X axis straightness Repeatability for Y axis Repeatability for Z axis Spindle rotation run out |

(mm) (mm) (mm) (mm) (mm) |

0.02 0.01/500 ±0.005 ±0.005 Radial direction 0.005 |

| Utility | Power Power consumption Air source pressure (option) Air consumption (option) |

(KVA) (MPa) (Nl/min) |

3 phase 200 V 50/60 Hz 8.0 0.55 60 |

| Coolant supply unit | Coolant water pressure Coolant consumption (Max) |

(MPa) (l/min) |

0.3 30 |

| Cooler unit | Power consumption (option) | (KVA) | 2.0 |

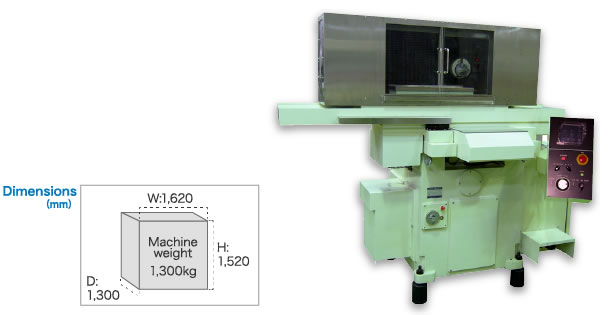

| Machine size | Main body only (excluding protrusions) | (mm) | 1,620 (W) x 1,300 (D) x 1,520 (at stop) |

| Machine weight | Main body only | (kg) | 1,300 |

*The specification of this machine may be changed for improvement without notice.

*Please contact our sales department for cutting application inquiries on this machine.