Cutting Machine Lineup

Fully Automatic SlicersDFS1100

Confidently cut thick materials such as glass, metal and ceramic with high accuracy and stability.

Fully automated work processes from workpiece setting to cutting and cleaning.

Features

- 1. Use OD diameter 4-inch blade

- 2. Equipped with air spindle of the direct-coupled high-power motor

- 3. Capable of cutting compound materials!

- 4. High rigidity and a robust cast iron base body

- 5. Use single and multi gang blades

Suitable Materials

■ Maximum thickness of workpiece: 15 mm

- Shape

- Suitable products

- ・Ceramics packages substrates

・Photo mask

- Type

- *Suitable for cutting

thick workpieces.

Structural Advantages

Loader that stores cassettes

Unloader, and the robot arm that transports a wafer to each unit

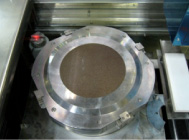

Wheel cover and blade breakage detector

Chuck table, dressing sub-table and non-contact setup sensor

Spinner cleaner that washes wafers after machining

Touch panel. A variety of auto alignment functions

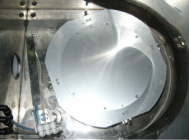

Cut with high aspect ratios!

Use the DFS1100 to cut 4 mmt soda glass to 4 mm deep.

The right angle to the cutting surface is 10 µm or less, and the kerf is cut straight without skew.

In spite of the high aspect ratio, the blade cuts into the glass vertically without bending.

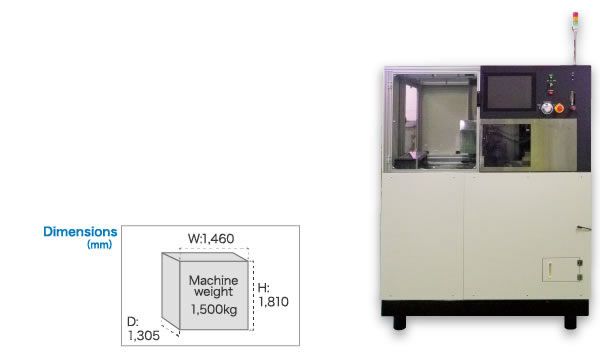

Standard Specifications

Fully Automatic Slicers

DFS1100

| Overview | Workpiece maximum diameter Frame type Cassette type 2-8-1, up to 25 slots |

(mm) | φ200 2-8-1 For 2-8-1, up to 25 slots |

|

|---|---|---|---|---|

| X axis | Workpiece clamp Stroke Movement amount command unit Maximum feed speed Speed command unit Axis drive system Drive source |

(mm) (mm) (mm/sec) (mm/s) |

Vacuum chuck 640 0.001 200 0.01 Rotates ball screw with motor shaft and drives X axis AC servo motor |

|

| Y axis | Stroke Movement amount command unit Maximum feed speed Speed command unit Axis drive system Drive source Axis control system |

(mm) (mm) (mm/sec) (mm/sec) |

200 0.001 50 0.001 Rotates ball screw with motor shaft and drives X axis AC servo motor Closed loop control by Magnescale |

|

| Z axis | Stroke Movement amount command unit Maximum rotation speed Speed command unit Axis drive system Drive source |

(mm) (mm) (mm/sec) (mm/sec) |

85 0.001 20 0.001 Rotates ball screw with motor shaft and drives X axis AC servo motor |

|

| W axis | Stroke Movement amount command unit Maximum rotation speed Speed command unit Axis drive system Drive source |

(°) (°) (°/s) (°/s) |

110(-10 - +100) 0.001 90 0.001 Directly rotated and driven by DD motor Direct drive motor |

|

| Spindle | Type Rotation speed range Rotation speed control system Motor Spindle tip dimensions Safety interlock |

(min-1) (kw) |

Motor built-in air spindle 10,000 - 15,000 Spindle inverter 3.7 2P Max. taper diameter φ36, taper 1/10 1. Spindle rotation stops if the waterproof cover opens. 2. Spindle cannot rotate while the cover is open. |

|

| Alignment | Type Micro: cell size Micro: View size Macro: cell size Macro: View size Work distance Lighting |

(μm) (mm) (μm) (mm) (mm) |

Micro and macro switching 2.1 (left and right) x 2.45 (forward and backward) 1.58 (left and right) x 1.19 (forward and backward) 16.8 (left and right) x 19.6 (forward and backward) 12.6 (left and right) x 9.51 (forward and backward) 150 Coaxial illumination via LED light source |

|

| Transport section | Compatible cassettes Number of usable cassettes Return type Cassette replacement method |

DTC2‒8J or equivalent 2 sets Back to the same slot Stopped by any interruption (Interruptions are disabled while cassette elevator is operating.) |

||

| Cleaning | Cleaning method Table revolutions Workpiece clamp method Revolutions and time instruction |

(min-1) |

2 fluids Up to 3,000 Frame clamp by vacuum and pendulum Workpiece clamp method Optional settings based on the program |

|

| Setup | Detection method Installation location |

Optical via fiber sensor On the X-axis slider |

||

| Blade breakage detector | Detection method Installation location |

Optical via fiber sensor Inside the blade cover |

||

| Automatic dressing | Dresser size Command system |

(mm) | 155 (length) x 50 (W) x 10 (thickness) Program |

|

| Accuracy | 1.Chuck table top accuracy 2.X axis straightness 3.Yawing along X axis straightness 4.Z axis index accuracy 5.Spindle rotation run out |

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) |

Yawing along X axis straightness Pitching Accumulative error Repeatability Accumulative error Spindle radial direction run out |

0.02/200 x 200 0.01/300 0.01/300 ±0.005/200 ±0.002 ±0.005/85 ±0.002 0.002 |

*The specification of this machine may be changed for improvement without notice.

*Please contact our sales department for cutting application inquiries on this machine.